Mercedes High-Strength Steel (HSS) is vital for modern airbag systems, enhancing passenger safety by maintaining structural integrity during collisions. Skilled technicians perform specialized repairs using precise cutting, welding, and shaping to preserve optimal airbag deployment timing. Adhering to best practices involving authentic parts, skilled labor, and proper preparation is crucial for safe and reliable Mercedes HSS repair, ensuring airbags deploy effectively when needed most. Regular auto maintenance, including detailing and car paint services, complements these efforts by preventing future damage.

Mercedes high-strength steel repair is crucial for maintaining the integrity and performance of modern airbag systems. This specialized metal plays a critical role in ensuring accurate timing during vehicle collisions, enhancing passenger safety. The article delves into the unique properties of Mercedes high-strength steel, exploring its essential role in airbag deployment precision. We also examine the significant impact of proper repair techniques on overall system accuracy and offer best practices for reliable Mercedes high-strength steel repairs.

- Understanding Mercedes High-Strength Steel and Its Role in Airbag Systems

- The Impact of Proper Repair Techniques on Airbag Timing Accuracy

- Best Practices for Mercedes High-Strength Steel Repair to Ensure Safety and Reliability

Understanding Mercedes High-Strength Steel and Its Role in Airbag Systems

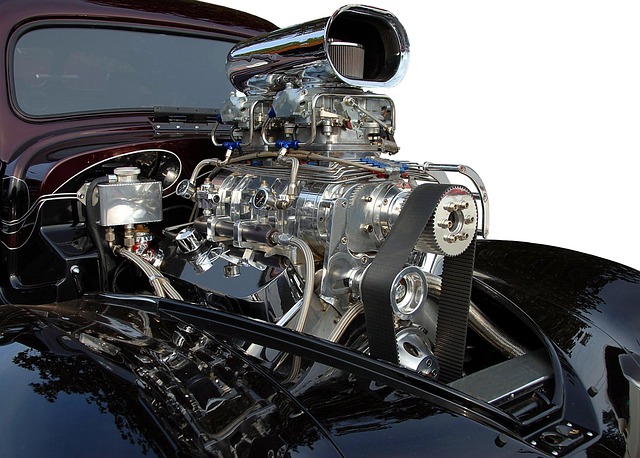

Mercedes High-Strength Steel (HSS) is a key component that plays a pivotal role in the intricate mechanisms of modern airbag systems. This advanced steel grade is renowned for its exceptional strength and durability, making it an ideal choice for automotive applications where precision and safety are paramount. In Mercedes vehicles, HSS is strategically incorporated into various structural elements, including panels, frames, and components within the airbags themselves. Its superior resistance to deformation ensures that in the event of a collision, these critical systems maintain their integrity and deploy precisely when needed.

Understanding the nuances of Mercedes HSS repair is essential for maintaining the integrity and reliability of airbag timing. Skilled technicians employ specialized techniques and tools to address any damage or degradation in this high-performance material without compromising its structural integrity. This meticulous process, often involving precision cutting, welding, and shaping, ensures that auto glass repair, bumper repair, or paintless dent repair procedures align seamlessly with the original vehicle specifications. By preserving the optimal performance of airbag systems, these repairs contribute to enhanced passenger safety and peace of mind for Mercedes owners.

The Impact of Proper Repair Techniques on Airbag Timing Accuracy

Proper repair techniques are paramount when it comes to maintaining the delicate timing accuracy of a vehicle’s airbags. In the case of Mercedes high-strength steel repairs, precision is key. Skilled technicians must carefully assess and address any damage to ensure that the airbag deployment system functions seamlessly in the event of an accident. The slightest misalignment or inconsistent repair can compromise the integrity of the entire system, leading to potential safety risks.

For instance, when conducting a bumper repair or vehicle body restoration involving high-strength steel, specialized tools and knowledge are required to retain the original timing specifications. This is crucial as even slight deviations in timing can affect the path and speed at which airbags deploy, potentially causing harm to occupants instead of protecting them. Therefore, adhering to meticulous standards during Mercedes high-strength steel repair processes directly contributes to the overall safety and reliability of the vehicle’s airbag system.

Best Practices for Mercedes High-Strength Steel Repair to Ensure Safety and Reliability

When addressing Mercedes high-strength steel repair, adhering to best practices is paramount for maintaining safety and reliability. This involves utilizing only authentic, high-quality replacement parts specifically designed for high-strength steel applications. Skilled technicians should perform the repairs, ensuring precise measurements and seamless integration with the vehicle’s existing structure. Proper cleaning and preparation of the damaged area are essential steps before applying any repair method to guarantee long-lasting results.

Moreover, regular auto maintenance plays a crucial role in preventing future damage. Auto detailing services can help identify potential issues early on, while car paint services should be considered for restoring cosmetic integrity without compromising structural integrity. By combining expert repairs with proactive auto care, Mercedes owners can ensure their vehicles maintain optimal performance and safety standards.

Mercedes High-Strength Steel (HSS) plays a critical role in ensuring the accurate timing of airbag deployment, a vital safety feature. Proper repair techniques for HSS are essential to maintain this accuracy, preventing potential hazards on the road. By following best practices for Mercedes HSS repair, including utilizing advanced technologies and skilled technicians, vehicle owners can rest assured that their airbag systems function optimally, safeguarding them and their passengers in the event of an accident.